Where You'll Learn by Doing

Based in Building 45

The Department of Apparel Merchandising & Management offers students an immersive, hands-on learning experience through its comprehensive lab facilities located in Building 45.

As a business and technology-driven program, nearly every course includes laboratory or activity sessions where students apply classroom concepts to real-world projects—developing the practical skills and industry knowledge needed to succeed in fashion design, production, and management.

From apparel production and textile testing to digital design, surface embellishment, and fashion business systems, the department’s labs are equipped with industry-standard tools and technologies that reflect the latest trends in fashion design, technology, and management.

Product Development and Production Lab

Our 3,000-square-foot Apparel Production Lab is an industry-grade facility that supports every stage of fashion manufacturing.

It features a wide array of Juki and Brother industrial sewing machines—including sergers, walking foot machines, zigzag, bartack, buttonhole, and multi-needle models—as well as specialized equipment for crafting accessories like bags and shoes.

Students gain hands-on experience with advanced systems, including the Eton computer-controlled Unit Production System, raised-bed sewing stations, and an ultrasonic bonding machine.

The lab also includes spacious pattern-making tables, professional dress forms, mannequins, and finishing tools.

Integrated digital technologies, including a full-size Size Stream body scanner and software such as Browzwear, TUKAstudio, and Gerber AccuMark, allow students to create digital avatars, visualize designs, and develop garments with precision fit—bridging traditional craftsmanship with cutting-edge apparel technology.

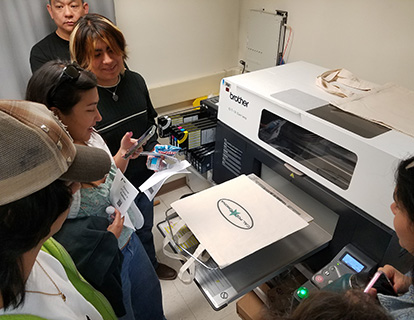

Digital Surface Design Lab

The Digital Surface Design Lab is a creative hub where students explore innovative methods of embellishing textiles and fashion products using advanced digital technologies.

The lab is equipped with professional digital embroidery machines, direct-to-garment (DTG) printers, a large-format sublimation printer for textiles, a small-format sublimation printer for fashion accessories, a 3D printer, and multiple heat presses.

This versatile setup enables students to design, print, heat press, and embroider directly onto fabrics and pre-finished garments, allowing for hands-on experimentation with surface treatments and custom detailing.

The lab fosters interdisciplinary design, blending traditional textile practices with cutting-edge digital production for fashion, accessories, and beyond.

Textile Lab

Our Textile and Garment Testing Lab is a fully equipped facility designed to provide students with in-depth knowledge of fibers, textiles, and the quality testing methods essential to the fashion industry.

The lab features a comprehensive range of instruments for testing fibers, yarns, fabrics, and garments in accordance with the American Society for Testing and Materials (ASTM) and American Association of Textile Chemists and Colorists (AATCC) standards.

Equipment includes the Instron tensile strength tester, Elmendorf tear strength tester, flammability tester, drape tester, SDL pilling tester, and Taber and Martindale abraders.

Color evaluation and dyeing processes are supported by spectrophotometers, a Datacolor infrared dyeing system, and a standard lighting cabinet.

Additional tools such as a Weather-Ometer, Launder-Ometer, and laundry and drying machines allow for extensive testing of durability and colorfastness. Through hands-on experience with this industry-standard equipment, students gain a strong foundation in textile science, preparing them to evaluate fabric performance and quality with precision and confidence.

Fashion Retail Micro Business Lab - BLDG45 Boutique

The BLDG45 Boutique, our fashion retail lab, offers senior fashion retailing students a hands-on capstone experience through the operation of a registered student-run fashion microbusiness, ApparelScapes.

In this real-world setting, students apply skills from fashion retailing and merchandising courses to analyze target customers, develop and source products, set pricing, and create visual merchandising and marketing strategies.

Using a Clover point-of-sale system with in-store and mobile card readers and barcode scanners, they manage sales and inventory.

This lab allows students to evaluate the performance of their designs and the microbusiness overall, preparing them for future careers in the fashion business and entrepreneurship.

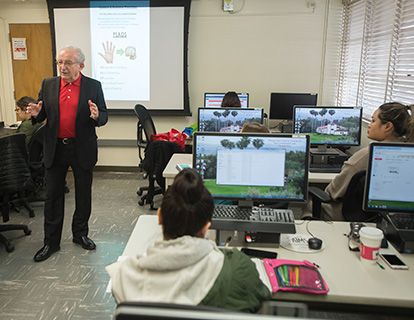

Computer Labs

Our three computer labs provide students with hands-on experience using industry-standard software essential for both fashion design and business operations.

These labs support a wide range of functions, including product design, digital patternmaking and draping, and technical package development.

Students work with leading tools, including Adobe Creative Suite, TUKAstudio Browzwear, Gerber AccuMark, and others, to develop their creative and technical skills.

In addition to design-focused applications, the labs also introduce students to the business side of fashion. They gain practical knowledge of enterprise resource planning (ERP), business information systems, and retail point-of-sale and data management platforms such as AIMS.

Students also learn to utilize data analytics tools, e-commerce management systems such as Shopify, and social media management platforms to plan, promote, and manage digital retail experiences. These comprehensive learning environments prepare students to thrive not only as designers but also as strategic thinkers and managers in the global fashion industry.