The Bridge to Nationals

By Taylor Jaseph

Photos by Jordan Chung

From the Editor: Every year, engineering students across the country compete in the annual Student Steel Bridge Competition. And every year, our civil engineering student team puts in their all. This year, among 250 regional competitors, Cal Poly Pomona was just one of 43 universities that qualified for national competition. Among the 43, our team earned seventh place. This was no easy feat. Student and co-project manager Taylor Jaseph tell us how the team did it.

It took our four-person construction team 10 minutes and 10 seconds to put together 50 individual steel parts to construct our 24-foot bridge. This time helped rank the Cal Poly Pomona Steel Bridge team seventh nationally.

Getting there was a journey of overcoming significant challenges and even doubt that we would have a bridge to compete with.

September 2022

Off the bat, the biggest challenge that persisted throughout the year was communication and sticking to our deadlines. In a team of 30 or so students, all with vastly different class schedules, it was difficult to communicate and find a time that worked for everyone. Consequently, we held our weekly officer meetings at 9 p.m. as this was the only time all the officers could get together.

I experienced this trouble firsthand as safety captain by trying to find times for safety trainings so our team could work in the lab. Because of the lack of communication and the difficulty of getting our whole group together in one place, some of our members never received the safety training needed to work in our lab space. All of this compounded into missing most of our deadlines and uncertainty clouding the team. With regional competition just two months away, we weren’t sure if we would have a bridge to compete with.

I experienced this trouble firsthand as safety captain by trying to find times for safety trainings so our team could work in the lab. Because of the lack of communication and the difficulty of getting our whole group together in one place, some of our members never received the safety training needed to work in our lab space. All of this compounded into missing most of our deadlines and uncertainty clouding the team. With regional competition just two months away, we weren’t sure if we would have a bridge to compete with.

Even through these doubts and struggles, we succeeded. It can be attributed to the consistency and excitement of our general members and officers. The team saw the greatest retainment of general members and officers since pre-pandemic times, enabling our team to grow and learn together across two years instead of starting from developing new relationships and learning from scratch.

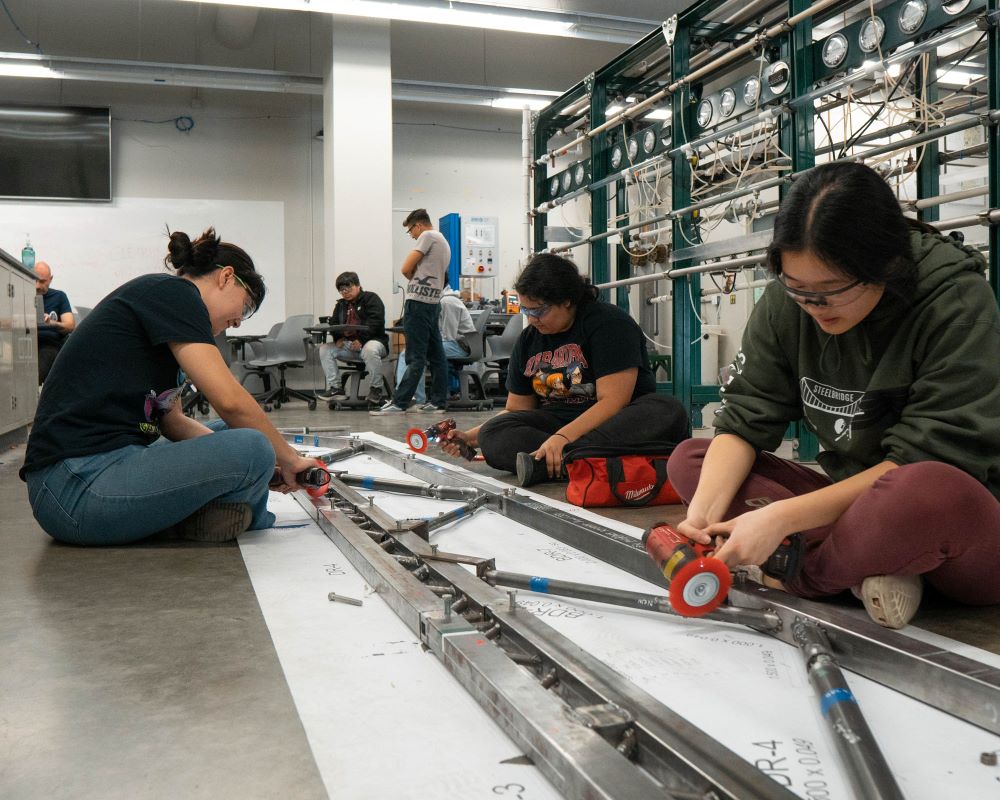

Everyone this past year dedicated the time and effort needed for the team to succeed, especially in fabrication. The team trained in different areas—such as measuring, cutting, grinding, polishing, and welding—to create the most efficient process of making each member (think of each member as a Lego piece, or in our case, a piece of steel tubing, for example) of the bridge.

Admittedly, the whole process was haphazard, but soon, we were sitting on the floor of the hydraulics lab with all 50 parts needed to build our 24-foot steel bridge, like pieces of a puzzle.

We began welding each piece. Our main welder and her team spent hours bent over a table or on the floor connecting these pieces to create the members. But then came the next problem: How were we going to connect the 50 individual members live at the competition? We needed our connections, which would be welded onto members, but we didn’t have the skills to machine these parts in-house. With our deadline rapidly encroaching, what ensued was a day of the whole team cold-calling machine shops, asking them to sponsor CPP’s Steel Bridge team by aiding in making our connections. It was a day of stress and anxiety, but that urgency powered the team. With everyone working together, we were able to find sponsors that machined our connections.

February 2023, Three Months from Regional Competition

I remember the first time we were able to construct part of the bridge after welding the connections on. I just got out of my class at 8:30 p.m. and walked past the backyard of building 17. Some of my teammates were out there and I walked up to them wondering why they were out so late. I found they were putting one side of the bridge together to see how the members fit. The excitement of the team was boisterous. Our construction team got comfortable holding the members and finding optimal ways to connect the pieces and insert the bolts to get us a good construction time.

After months of all our hard work of designing, fabricating and now, constructing a bridge, I finally saw the Pacific Southwest

Symposium (PSWS), not as a distant competition, but as something we will be competing in and possibly winning. And we did win, at least for a moment. At PSWS, we were the last team of the day to construct and came out with the fastest raw construction time of 11 minutes and 43 seconds, effectively earning our place at the national finals for steel bridge in San Diego.

Since we were the last team to go at PSWS, we were three hours late to the banquet and award ceremony—it wouldn’t be the CPP Steel Bridge team if we weren’t a little past the deadline—where we were announced first overall in the competition. What ensued was absolute chaos. It was not just the Steel Bridge team celebrating the win, but every competition team from CPP cheered us on, congratulating us as we all ran to the front.

We learned not too long after, that there was an error in the scoring—we actually were second place. We still qualified for nationals, but it was a bit disappointing when the hosts of PSWS gave us the news.

But this was fuel for the fire—we wanted more than ever to prove ourselves at nationals.

Which we did. We ended up ranking seventh overall, fifth in construction speed, eleventh in stiffness and fourth in economy, to name a few categories.

The second we finished celebrating our nationals placement, we began preparing ourselves to do and be even better this coming year at Hawaii for regionals and then Louisiana for nationals.

Trial by Fire

The CPP Steel Bridge team unanimously stands behind CPP’s motto of learn by doing. Through this whole journey, we gained hands-on experience that is difficult to truly simulate in a classroom. This past year, we learned from the challenges, the successes and each other.

It’ll be exhausting, stressful and we’ll have moments where we’ll doubt our ability to deliver. And we’ll be there, ready to compete again.

Jordan Chung is a third-year general civil engineering student at Cal Poly Pomona and co-project manager for the CPP Steel Bridge team, previously serving as quality control.

Taylor Jaseph is a fourth-year general civil engineering student at Cal Poly Pomona and co-project manager for the CPP Steel Bridge team, previously serving as the safety captain. She is also the copy editor for the news and opinion sections for the university paper, The Poly Post.